Project application

enterprise-orientedsupplemented by Huihe Huade

safety assessment data

environmental assessment data

D+EPC

Microreaction, continuous flow process development and industrialization services

D+

Development

D+,Level up process development,"begin with the end in mind" +Hybrid......

E

Engineering

P

Procurement

C

Construction

EPC,"One-stop""Turnkey".ultra-flux,third generation,easy maintenance, cost reduction and efficiency improvement, stable operation

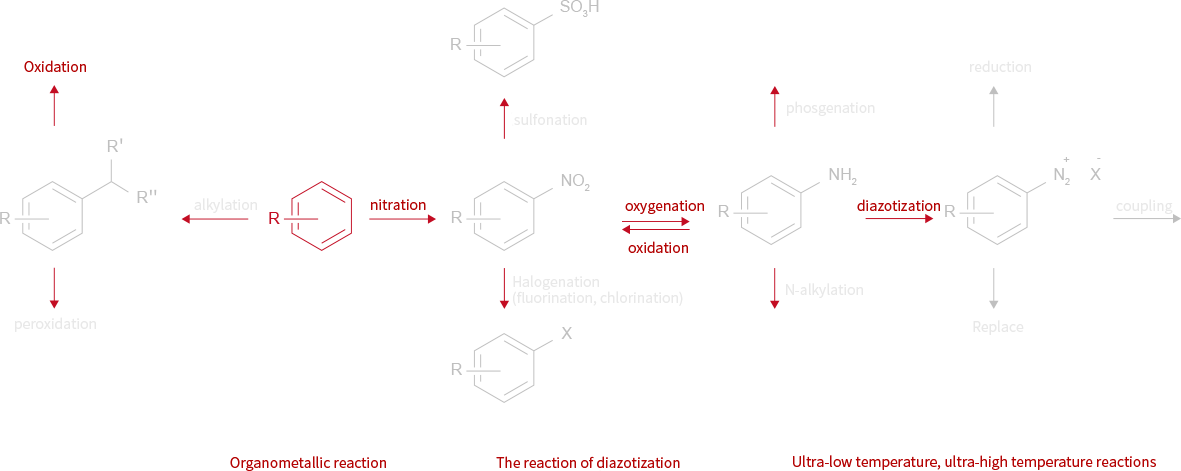

High-risk processes

Difficult projects

Lack of cross-disciplinary teams

Focus on high success rate

First contact with micro-reaction technology

Project Consultation and Evaluation Services

Zero cost, come for "fortune telling", reduce risk, take shortcuts.

Micro-reaction Process Package Development Service

Guiding the engineering process well can bring big returns with small investment!

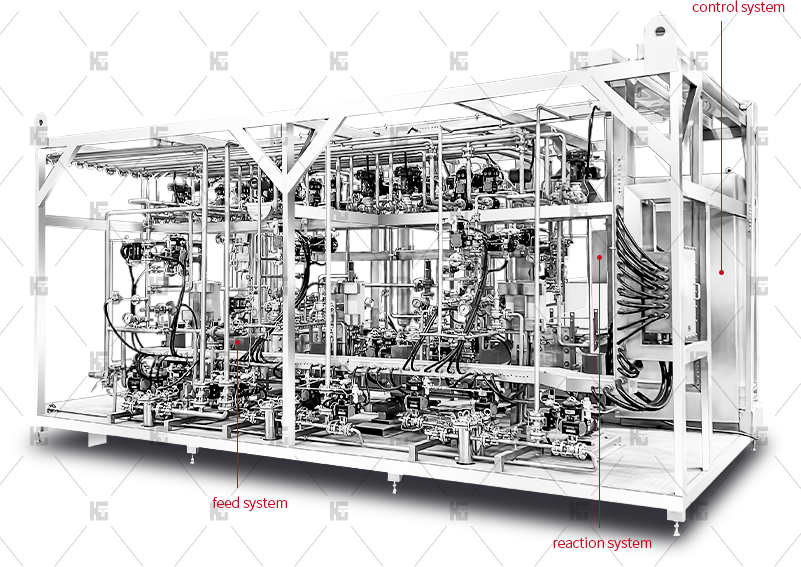

Design and Manufacturing of Micro Reaction System Equipment

A fully automated "container" factory under the "one-stop" "turnkey" service!

Two weeks

Project evaluation

Hybrid-Chem Technologies

Technical

Financial evaluation

Project cycle

Three months

Process development

Hybrid-Chem Technologies

Feasibility verification

Process development

Process optimization

Two weeks

Process safety analysis

Hybrid-Chem Technologiesand Shanghai Chemical Research Institute

Process hazard level

Material stability

Five months

Project application

enterprise-orientedsupplemented by Huihe Huade

safety assessment data

environmental assessment data

Equipment construction

Hybrid-Chem Technologies

Equipment design

Equipment procurement

Equipment construction

One month

Factory driving

Hybrid-Chem Technologies

device testing

device driving

worker training

Third-generation Micro-reaction Continuous Flow Skid-mounted Equipment

Introduction of the device

Product Type: Pesticide Intermediates

Reaction Type: Nitration Reaction

Development of a continuous flow process incorporating reaction distillation and wastewater treatment research

100% conversion rate, 97% reaction yield (external standard method)

In addition to process research on the reaction section, this project also conducted process research on distillation and wastewater treatment for customers

Annual output of 1500 tons

Third-generation skid-mounted equipment, highly integrated, easy to maintain, one-key start and stop

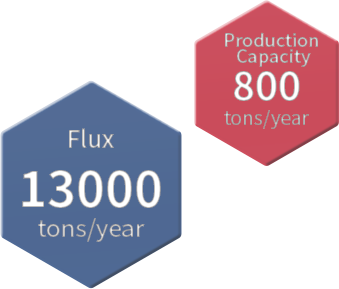

The world's first ten-thousand ton micro-reaction continuous flow equipment

Introduction of the device

Product Type: Pesticide Intermediates

Reaction Type: Diazotization Reaction

The full process yield has increased by 15%

The production is essentially safe, with a 99.99% reduction in the volume of liquid held in the diazotization step

The volume of liquid held in the hydrolysis step is reduced by 96.5%

The footprint of the production unit is reduced by 90%, and manpower is decreased by 80%

Reduction in the emission of "three wastes" and energy consumption

The annual net profit of the owner has greatly increased